ISKRA - THE TOOL THAT’S REVOLUTIONIZING CUSTOM CABINET PRODUCTION

Meet the Iskra Drill – a tool designed specifically for cabinetmakers and woodworking professionals creating custom-built kitchens, wardrobes, and other cabinet systems.

With Iskra, you can quickly and accurately drill all essential round holes required for connectors, hinges, and shelf supports from various manufacturers, ensuring repeatable precision and compatibility with a wide range of standard fittings. It’s the perfect solution for both workshop use and on-site jobs.

Thanks to Iskra technology, you can also prepare pre-drilled cabinet parts for flat-pack production, enabling customers to assemble their cabinets on-site – an ideal solution for modern, scalable cabinet making.

Precision, mobility, and versatility – all in one tool.

SW3 WORKTABLE

The SW3 worktable is an essential tool in every professional cabinetmaking workshop, enabling precise drilling of holes in cabinet panels. Supporting both the metric system and the popular 32 mm system, the table offers great versatility and significantly enhances the quality of work.

Investing in the SW3 worktable is a step toward more efficient production and higher-quality finished cabinets that meet the expectations of the most demanding customers.

ONE DRILL – TWO METHODS OF WORK

The ISKRA RX2 Positioner is a dedicated tool designed to complement ISKRA technology and meet the demands of the cabinetmaking industry.

With ISKRA, you get the flexibility to choose your workflow: use the drill with the SW3 worktable for stable, system-based drilling, or go fully mobile with the RX2 Positioner for precise on-site work on both panel surfaces and edges.

Whichever method you choose, you get precision, repeatability, and total control.

A perfect kitchen starts with precision

With ISKRA technology, every component fits flawlessly, making the assembly process fast and effortless.

It’s a solution designed for professionals who understand that true quality begins in the workshop – and ends in beautifully crafted cabinetry.

KEY PARAMETERS

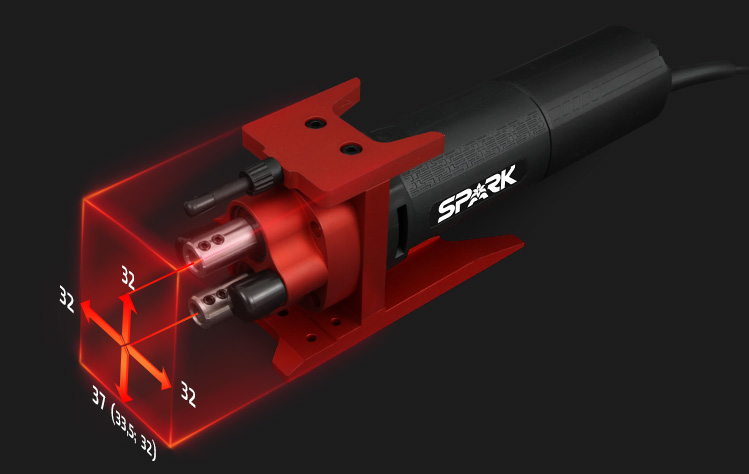

Our drill operates precisely along three axes: X, Y, and Z, ensuring accurate drilling in every direction.

Electronic speed stabilization maintains a constant rotation speed regardless of load, guaranteeing repeatability and high-quality results.

The adjustable rotation speed range from 1100 to 4300 RPM allows you to tailor the settings to different materials and production requirements.

The design features a 32 mm distance from the drill edge to the spindle axis and a 32 mm spacing between spindles, perfectly aligning with the 32 mm system standards, which greatly facilitates assembly and compatibility with furniture connectors.